Planning Your Schedule: Realistic Time Expectations for Your Car wrap

That moment you decide to wrap your car is pure excitement. But it’s always followed by the big question: "So, how long will I be without my car?" The truth is, there's no single answer. Your vehicle's size, its body lines, and the complexity of your design all dramatically shape the timeline. From essential prep work to the final curing stage, I’ll break down the day-by-day process and the key factors that affect your car's wrapping time. Let’s set a realistic expectation for your project’s schedule.

1. The Biggest Factor in Car Wrapping Time: Vehicle Size and Shape

This is the most fundamental variable. Think of it like painting a room: a small bathroom is quick, while a great hall with high ceilings and intricate trim takes significantly longer. A compact car like a Mini Cooper has a relatively small, simple surface area. An installer can maneuver around it easily. Now, picture a massive crew-cab truck like a Ford F-350 or a vehicle with complex curves and sharp body lines, like a new Corvette. The truck has vastly more square footage of vinyl to handle, while the Corvette demands extreme precision to stretch and seam the film around its dramatic contours without wrinkles. A simple sedan might be a 2-3 day job, while a large, complex vehicle can easily push into a 4-5 day timeframe.

2. How Design Complexity Drastically Alters Your Wrap Timeline

A single, solid color wrap is the most straightforward process. The installer works with large, continuous panels of vinyl. The moment you introduce complexity, the clock starts ticking longer. A two-tone design? That requires precise measurement, laser-straight lines, and additional seaming. A full custom print with graphics, logos, or racing stripes? This adds massive amounts of time for design alignment alone. The installer must position the printed vinyl perfectly so that the graphic flows seamlessly over doors, fenders, and bumpers. This "juggling" of the design across the car's body is a painstaking process that can add a full day or more compared to a solid color.

3. A Day-by-Day Breakdown of a Professional Car Wrap Process

Let's demystify what actually happens each day your car is in the shop.

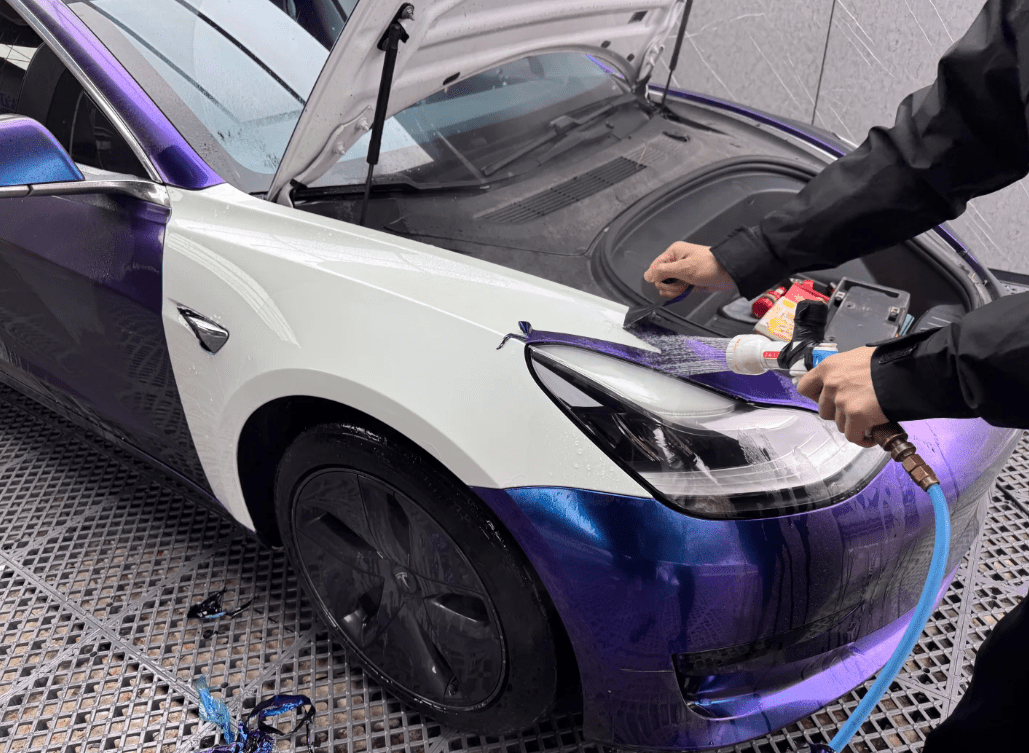

- •Day 1: The Deep Clean & Prep. This is arguably the most critical day. The car is thoroughly washed, then decontaminated with a clay bar to remove embedded pollutants. All emblems, handles, and trim pieces that can be removed are taken off. The vehicle is then wiped down with an isopropyl alcohol solution to ensure a perfectly clean, oil-free surface for the vinyl to adhere to. Rushing this step guarantees a failed wrap.

- •Day 2-3 (or 4): The Main Installation. This is when the vinyl goes on, panel by panel. A skilled installer works methodically, starting with the larger, flatter surfaces like the hood and roof before tackling the complex bumpers and mirrors. They use heat guns to gently soften the vinyl, allowing it to conform perfectly to curves and recesses without stretching it too thin.

- •Day 4 (or 5): The Final Day - Reassembly & Curing. All removed parts are reinstalled. The entire vehicle is inspected inch-by-inch under bright lights for any dust, bubbles, or lifting edges. Finally, the car is left indoors to "cure." The adhesives need time to fully bond to the paint, which is essential for long-term durability.

4. Vinyl Wrap vs. Paint Protection Film: Is One Faster to Apply?

Generally, a colored vinyl wrap is faster to install than Paint Protection Film (PPF). Why? Vinyl is thicker and less stretchy. Installers often work in larger sections and can be more aggressive with seams that are hidden in body lines. PPF, however, is ultra-thin and incredibly stretchy. The installation process is more like laying a giant, wet, sticky contact lens over each panel. It requires more precision, specialized solutions, and a slower, more meticulous hand to avoid stretching the film, which can cause optical distortions. A full PPF installation is a premium service that almost always takes longer than a full vinyl wrap.

5. How a Partial Wrap Can Slash Your Car Wrapping Time in Half

A partial wrap is exactly what it sounds like: covering only specific sections of the car, like the hood, roof, and mirrors, or creating racing stripes. Since you're not wrapping the entire vehicle, the time commitment plummets. What might be a 3-4 day full wrap project can often be completed in a single day or two as a partial. This is a fantastic option for those wanting a dramatic visual impact without the full time and financial investment.

6. The Prep Work: Why Surface Preparation is Crucial (and Time-Consuming)

I cannot overstate this: the quality of the prep work dictates the quality and longevity of the entire wrap. Any dirt, wax, or contaminant trapped under the vinyl will be visible as a bump and create a failure point. The meticulous washing, claying, and alcohol wiping process ensures a surgically clean canvas. This stage isn't glamorous, but it's non-negotiable. Skipping or rushing prep is a guarantee that the vinyl will not adhere properly and will lead to peeling, bubbling, and a short lifespan for your investment.

7. Does the Installer's Experience Shorten Car Wrapping Time?

Absolutely. An experienced installer works with an efficiency and confidence that dramatically impacts the timeline. They have the muscle memory to handle complex curves quickly, know exactly how much heat and stretch to apply for the wrap, and can problem-solve on the fly. A less experienced installer may work slower, make mistakes that require redoing sections, and lack the streamlined process of a veteran. While you might pay a premium for an expert, you're often paying for a faster, higher-quality result with fewer headaches.

8. The Curing and Drying Phase: The Final, Often Overlooked, Step

Once the last piece of vinyl is down, the job isn't quite finished. The adhesives need time to reach their full bond strength with the car's paint. This "curing" period typically takes 24-48 hours. During this time, you should avoid washing the car, driving at high speeds, or exposing it to heavy rain. This allows the vinyl to set completely, ensuring edges stay down and the wrap can withstand the elements for years to come.

9. Can You Speed Up the Process? The Trade-Offs of a Rushed Wrap

You can sometimes find a shop that promises a "24-hour wrap." This almost always involves significant compromises. It typically means multiple installers working on the car simultaneously ("assembly line" style), which can increase the risk of errors. It almost certainly means less meticulous prep and post-installation inspection. The result is often visible seams in the wrong places, trapped dust, and a shorter-lasting finish. A quality wrap is a craft, not a race. Rushing it inevitably sacrifices quality for speed.

10. Planning Your Schedule: Realistic Time Expectations for Your Car

So, what's the bottom line? For a standard sedan or coupe with a solid color wrap, planned by an experienced installer, you should expect a 3-day timeline. For a larger SUV/truck or a vehicle with a complex design, budget for 4-5 days. Always ask your installer for their specific estimate based on your vehicle and vision. This ensures you can plan your transportation accordingly and have peace of mind knowing your car is in good hands.

1. What's the average time to wrap a car?

There's no true "average," but for a standard sedan or coupe with a solid color, a professional installation typically takes 2 to 3 full days. This includes essential prep, installation, and a final inspection. Larger vehicles like trucks and SUVs, or cars with complex designs, will take 4 to 5 days.

2. Why does it take so long? Can't it be done faster?

The time is dedicated to precision. Rushing leads to bubbles, poor adhesion, and visible seams. The process involves a deep clean, careful removal of parts like handles and emblems, meticulous panel-by-panel application, and a crucial curing period for the adhesive to bond fully. Quality craftsmanship simply can't be hurried.

3. What's the single biggest factor that affects the time?

The vehicle itself. A large SUV has more surface area than a small car, which takes longer. More importantly, a vehicle with sharp body lines, complex curves (like a new BMW or Corvette), and lots of intricate details requires significantly more time to wrap properly than a car with simple, flat panels.

4. Is a partial wrap much faster?

Yes, significantly. A partial wrap, such as covering just the roof, hood, and mirrors, can often be completed in a single day. Since you're not wrapping the entire vehicle, the time commitment and cost are much lower while still achieving a dramatic visual impact.

5. What happens if I need my car back sooner and rush the process?

Rushing the process is the biggest risk to a successful wrap. It almost always means compromising on the essential prep work or final inspection. The result will likely be trapped dirt, premature peeling at the edges, and a finish that lacks the flawless, professional quality you're paying for. It's an investment that benefits from patience.

In the end, the time required for a car wrap is a direct reflection of the quality you can expect. It’s not just about applying vinyl; it’s about meticulous preparation, skilled installation, and proper curing. Understanding the factors that influence the timeline—your vehicle's size, design complexity, and the installer's expertise—empowers you to plan confidently. A great wrap is an investment in craftsmanship, and that simply can't be rushed. The final result, a head-turning transformation that lasts for years, will make every day of the wait worthwhile.