CARLIKE Car Wrapping Vinyl

CARLIKE CL-ES-16 Electro Metallic Satin Orange Vinyl

Choose options

Series: 3000

Brand: CARLIKE

Color: Electro Metallic Satin Orange

Model number: CL-ES-16

Characteristic: Super stretch, incredible restorable

Performance level: Premium+

Film produce technology: High polymeric with double casting

Film thickness: 160micron, 6.4mil (with glue)

Release paper: 160g/m2, silicone coated

Adhesive thickness: 30μm

Air bubble free: Yes

Application: Car wrap

Application temperature: From +80°С to +120°С

Temperature resistance: From -40°С to +120°С

Storing period: 2 years if stored in +10°С to +25°С, relative humidity 50%, in original package, away from direct sunlight, clean and dry place

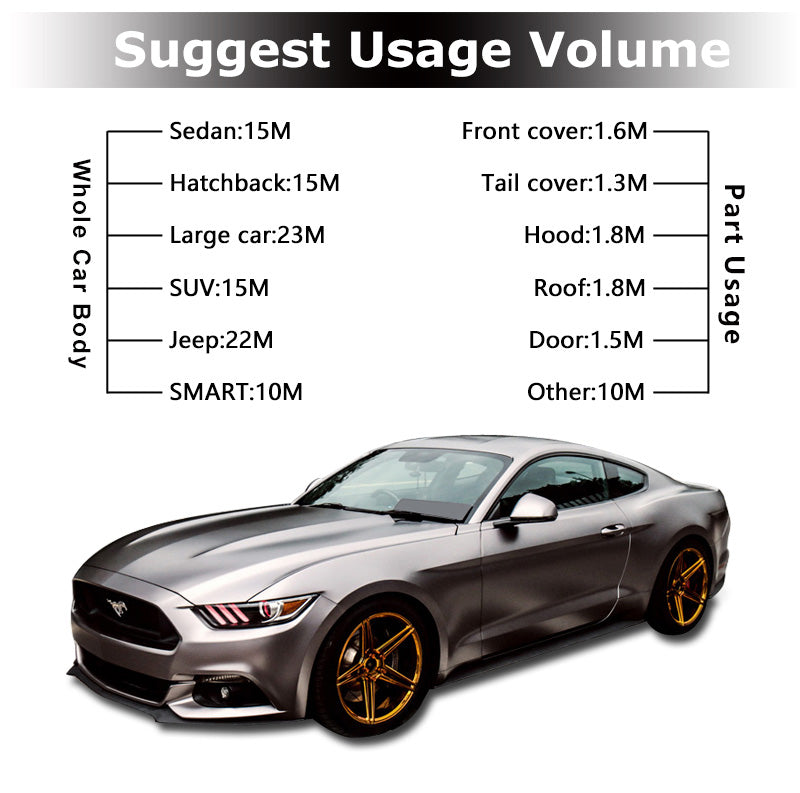

Package: Full roll width 1.52m, length 17m, weight 13KG

Packing size: 1.55x0.18x0.18m

Remark: the full roll 1.52x17M/5x56FT usually is enough for wrap a full sedan or SUV. If your car is larger, please choose 1.52x23M/5x75FT, we will send 1.52x6M/5x19FT + 1.52x17M/5x56FT.

Quality warranty: 2 Years, during the quality warranty period, the film surface has no obvious fading, no cracking, and no residual glue on the car paint after removable.

| Data Sheet | |

| Surface | Opaque |

| Substrate material |

130Microns High Polymeric PVC |

| Pressure sensitive adhesive |

30μm Solvent-based Removable |

| Releaser liner | 160G double PE coating High density air channels |

| Elongation at break |

300% |

| Tear strength | 37.2 N/10mm Test Method: ASTM D3759 |

| Glossiness | Gloss 95-110Gu Matte 5-30Gu |

| Viscosity | Initial tack:700-800g/25mm After 24 hours:1800-2000g/25mm After 3 months: 1500g/25mm |

| Peel strength | 2.5N/25mm Test Method: ASTM D3330 |

| Temperature resistance | -40°С to +120°С |

| Flourescent ultraviolet test |

Gray Level: 4-5 Test Method: ASTM D4329-13A |

Caution: The product images, colors on the screen are approximate. For the real representation of the product color, please check the color swatch.

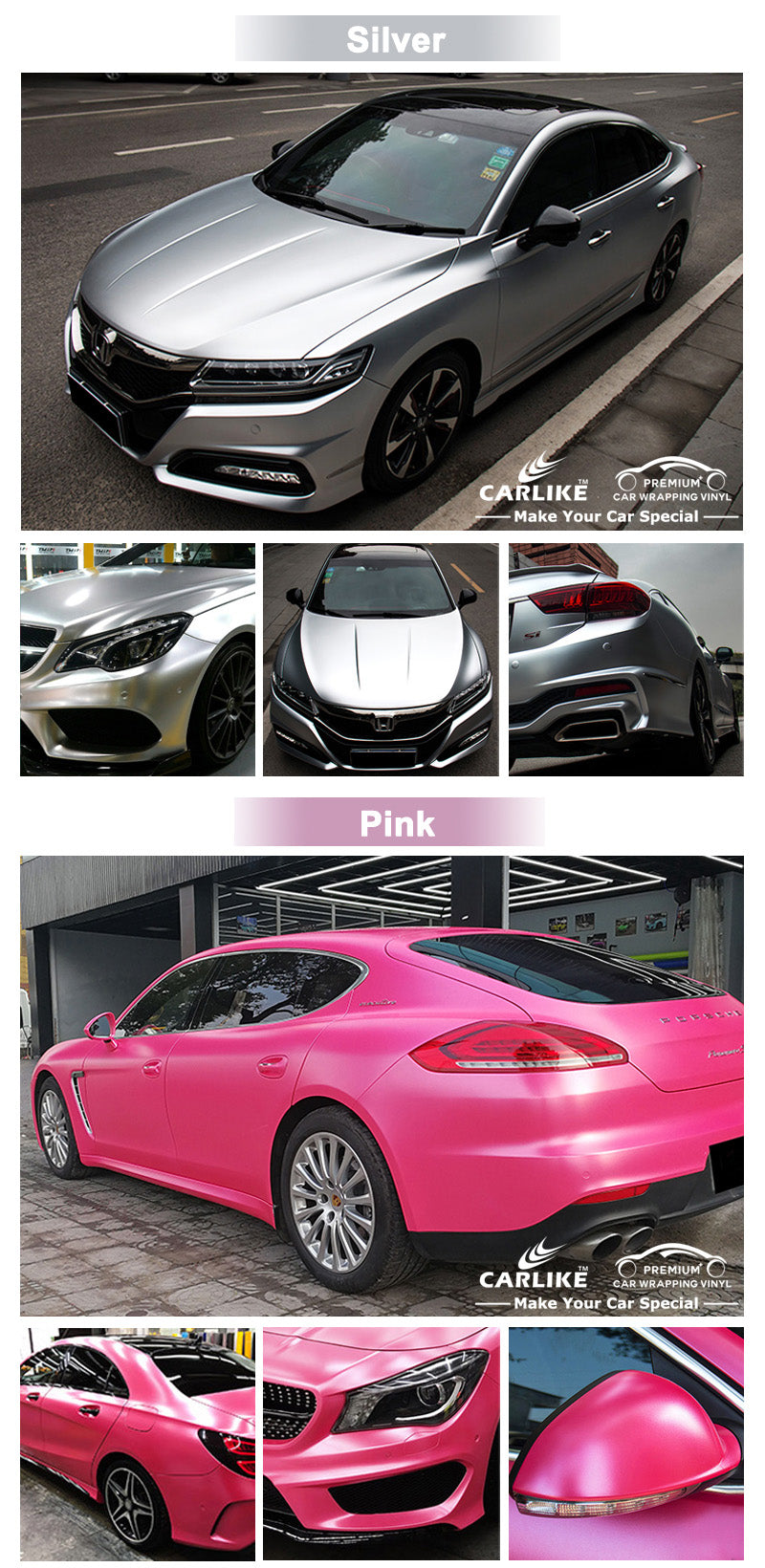

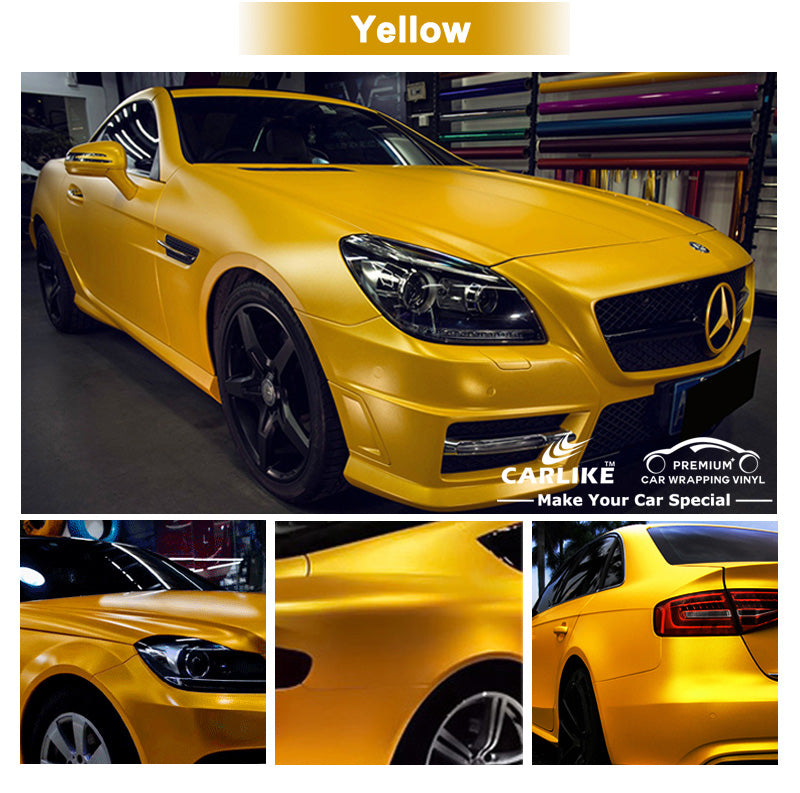

Electro Metallic Satin Orange Vinyl Car Wrapping is a specialized technique used to change the appearance of a vehicle by applying a thin layer of vinyl film to its exterior surface. In this case, the vinyl film used has an electro metallic satin orange finish, which gives the car a distinct and eye-catching appearance.

Car wrapping has gained popularity as an alternative to traditional paint jobs due to its versatility, cost-effectiveness, and ease of application. Vinyl wraps are available in various finishes, colors, and textures, allowing car owners to achieve unique looks and protect the original paintwork simultaneously.

The electro metallic satin orange vinyl used in car wrapping is designed to mimic the appearance of metallic paint, giving the vehicle a glossy, metallic sheen. It creates a stunning visual effect as light reflects off the surface, highlighting the curves and contours of the car. The satin finish provides a smooth and refined appearance while reducing the level of reflection compared to a high-gloss finish, giving the vehicle a more sophisticated and subtle look.

One of the primary advantages of using vinyl wraps for car customization is their durability and protective qualities. The vinyl film acts as a shield against minor scratches, stone chips, UV rays, and other environmental factors that can damage the underlying paint. This protective layer can help preserve the car's original paintwork, increasing its resale value.

The process of applying an electro metallic satin orange vinyl wrap to a car involves several steps. Firstly, the vehicle's surface needs to be thoroughly cleaned and prepared to ensure proper adhesion of the vinyl. This includes removing any dirt, grease, or wax, as well as repairing any existing paint damage.

Once the surface is clean, the vinyl wrap is carefully applied using heat and pressure. The vinyl is cut into precise shapes and sizes, customized to fit the specific contours of the car. Skilled installers use specialized tools like heat guns and squeegees to stretch and manipulate the vinyl, ensuring a seamless and bubble-free finish.

Proper installation is crucial to achieving a high-quality result, and it requires expertise and experience. Therefore, it's recommended to have the car wrapping performed by professionals who have the necessary skills and knowledge to ensure a flawless application.

One of the significant advantages of car wrapping is its reversibility. Unlike a traditional paint job, vinyl wraps can be removed without causing any damage to the original paintwork. This feature allows car owners to change the vehicle's appearance whenever they desire or remove the wrap entirely, returning the car to its original state.

In summary, Electro Metallic Satin Orange Vinyl Car Wrapping is a specialized technique used to transform the appearance of a vehicle. By applying a thin layer of vinyl film with an electro metallic satin orange finish, car owners can achieve a unique and attention-grabbing look while protecting the underlying paintwork. The process involves thorough surface preparation, precise application, and professional installation. Car wrapping offers durability, protection, and the ability to change the vehicle's appearance without permanently altering its original paint.